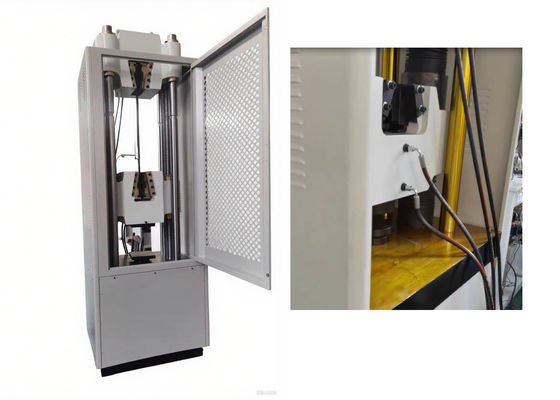

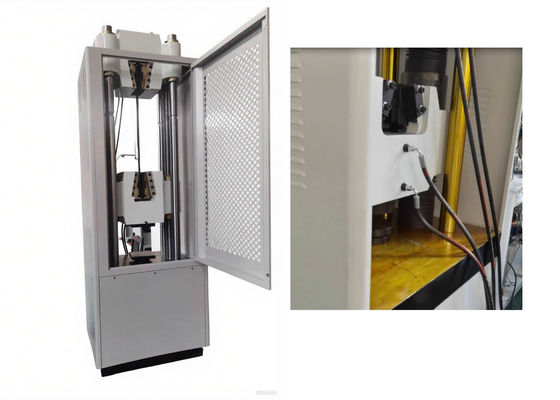

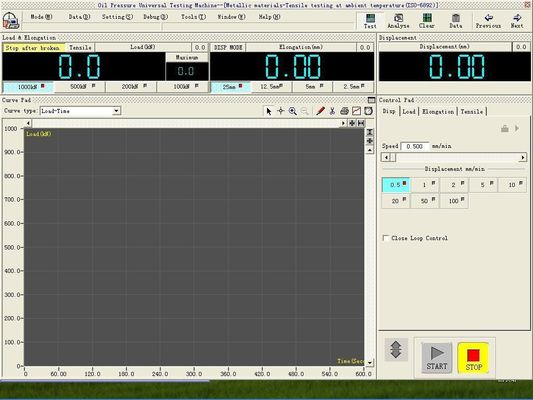

Servo-hydraulische testmachine met computergestuurde testoperatie en realtime gegevensweergave voor nauwkeurige materiaalanalyse

Toepassing

De ISO-compliant Servo Hydraulische Testmachine voor Stranded Steel Wire Tensile Testing heeft een brede toepassingsmogelijkheid en ondersteunt trek, compressie, buiging, scheer, schil,en andere mechanische eigenschappen testen op metaal, niet-metalen en composietmaterialen.

Zowel de testoperatie als de gegevensverwerking zijn volledig in overeenstemming met GB/T 228-2010 Metalen materialen - Trekproef bij omgevingstemperatuur - waarbij de testresultaten nauwkeurig en betrouwbaar zijn,en voldoet aan de nationale technische normen.

Het volledige testproces is volledig geautomatiseerd via computerbesturing, met realtime visualisatie van testgegevens, automatische generatie van meerdere testcurves (bijv.de verlenging van de verlenging van de verlenging van de verlenging van de verlenging, alsmede beveiligde gegevensopslag en print-on-demandfunctionaliteit.

Deze hoogwaardige testapparatuur wordt op grote schaal gebruikt in belangrijke sectoren, waaronder metallurgie, bouw, lichte industrie, luchtvaart, ruimtevaart, materialenwetenschappen, universiteiten,- als kerninstrument voor materiële kwalificatie, productkwaliteitscontrole en O&O-innovatie.

Prijsvoordeel

We hebben onze eigen R&D-initiatieven aanzienlijk geïntensiveerd, een speciaal bewerkingscentrum opgericht en zelfstandig kerncomponenten vervaardigd.Deze verticale integratie maakt het mogelijk om de kosten te optimaliseren in alle schakels van de toeleveringsketen zonder afbreuk te doen aan de kwaliteit van het product.

Onze kwalitatief hoogwaardige testapparatuur levert een grotere kostenbesparing op de lange termijn in vergelijking met goedkope, minder kwalitatieve alternatieven.We verminderen niet alleen de onderhoudskosten van onze klanten, maar verbeteren ook de operationele efficiëntie..

Deze optimale kwaliteits-kostenverhouding levert tastbare, duurzame waarde aan onze klanten, waarbij betrouwbare prestaties in evenwicht worden gebracht met economische voordelen.

Nalevingsnormen

ISO 6892, ISO 6934 BS4449, ASTM C39, ISO75001, ASTM A370, ASTM E4, ASTM E8 en BSEN-normen.

ASTMA370, ASTME4, ASTME8, ASTME9, ASTMA615, ISO6892, ISO7438, ISO7500-1, ISO 15630 ISO 6934, EN10002-4, GB/T228-2002, GB 16491-2008, HGT3844-2008 QBT 11130-1991, GB13-22-1991, HGT 3849- 2008,GB6349-1986, GB/T 1040.2-2006, ASTM C165, EN826, EN1606, EN1607, EN12430 enz.

Host kenmerken

De microcomputergestuurde elektro-hydraulische servo universele testmachine integreert automatische besturing, nauwkeurige meting, gegevensopname, realtime display op het scherm,en analyse van testresultaten in één geïntegreerd systeemHet heeft een ondercilinder-hoofdmotor als kernplatform.uitgerust met een hoogprecisie-oliepomp en een op de PC gebaseerde servo-controller -- waarmee een meerkanaals gesloten-lusbesturing mogelijk is om het testproces volledig te automatiseren, met inbegrip van automatische besturing en nauwkeurige meetfuncties.

Belangrijkste productkenmerken zijn sterk technisch professionaliteit, hoge operationele betrouwbaarheid en gemakkelijke upgradebaarheid.De functionaliteit kan voortdurend worden verrijkt en geoptimaliseerd in overeenstemming met de vooruitgang van de meet- en besturingstechnologie van de testmachine en de updates van de internationale/nationale testnormen, waarbij de verenigbaarheid op lange termijn met de veranderende behoeften van de industrie wordt gewaarborgd.

Belangrijkste technische parameters

| Model |

WAW-300D |

| Max. testkracht ((kN) |

300KN |

| Structuur |

Vier kolommen, twee kogelschroeven, oliecilinder-afsteltype |

| Beperkingsgebied |

1%-100% |

| Verhoogingssnelheid van het middenlicht (mm/min) |

250 mm/min |

| Max. trekruimte (mm) |

700 mm |

| Max. compressieruimte (mm) |

600 mm |

| Pistonstrek ((mm) |

200 mm |

| Vergrendeling van de spanning van de spanningsdraad |

Φ4-32 mm |

| Totaal vermogen |

2.2 kW |

| Grootte van de compressieplaat |

Φ160 mm |

| Afstand van de rollen voor de buigondersteuning |

300 mm |

Vaak gestelde vragen

V1: Is uw bedrijf een handelsonderneming of een productiefaciliteit?

A1: Wij opereren als een geïntegreerde productie- en handelsonderneming, met 18 jaar toegewijde focus op de testinstrumentensector en 14 jaar exportervaring.Ons verticaal geïntegreerde model combineert in-house productiecapaciteiten met wereldwijde handelsdiensten om kosteneffectieve, oplossingen van hoge kwaliteit.

V2: Hoe kan ik het meest geschikte product voor mijn behoeften kiezen?

A2: Ons professionele technische team zal op maat gemaakte aanbevelingen doen zodra u uw specifieke testvereisten heeft gedeeld, met inbegrip van testsoorten, toepasselijke normen, steekproefspecificaties,en prestatieparametersWe maken gebruik van de expertise van de industrie om u de optimale apparatuuroplossing te bieden.

V3: Wat zijn uw leveringsvoorwaarden?

A3: In de meeste gevallen hebben wij standaardmodellen op voorraad in onze fabriek voor directe verzending.de standaard termijn is 15-20 werkdagen na ontvangst van de voorschotbetalingAls u dringende eisen heeft, kunnen we prioritaire productie regelen om de leveringscyclus te verkorten... informeer ons dan over uw tijdschema voor speciale coördinatie.

Q4: Biedt u aanpassingsdiensten?

A4: Ja, we bieden uitgebreide aanpassingsdiensten. Naast ons standaard productassortiment kunnen we op basis van uw unieke technische vereisten aangepaste testinstrumenten ontwikkelen,toepassingsscenario'sWe moedigen u aan om gedetailleerde specificaties te delen, en onze R&D en engineering teams zullen ernaar streven om aan uw aanpassingsvereisten te voldoen.

Uw bericht moet tussen de 20-3.000 tekens bevatten!

Uw bericht moet tussen de 20-3.000 tekens bevatten! Controleer uw e-mail!

Controleer uw e-mail!  Uw bericht moet tussen de 20-3.000 tekens bevatten!

Uw bericht moet tussen de 20-3.000 tekens bevatten! Controleer uw e-mail!

Controleer uw e-mail!