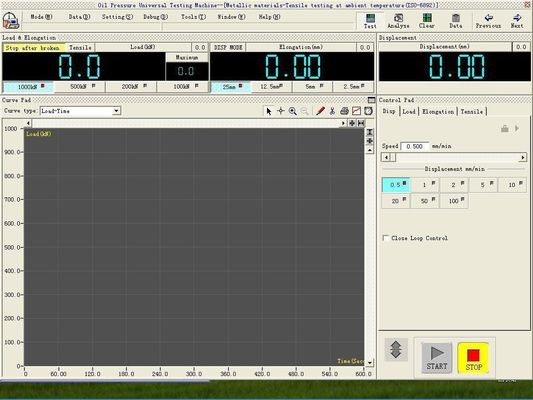

ISO Standaard Servo-Hydraulische Testmachine

Deze universele testmachine is uitgerust met een computergestuurd hydraulisch laadsysteem en een LCD-scherm met groot formaat, waardoor een gebruiksvriendelijke, intuïtieve bediening met gestroomlijnde workflows mogelijk is.

Toepassing

- Ontworpen voor het testen van mechanische eigenschappen van metalen materialen, ter ondersteuning van kern testmodi, waaronder trekken, compressie, buigen, afschuiven en aangepaste mechanische tests

- Flexibel aangepast voor het testen van niet-metalen materialen (hout, beton, cement, rubber) met optionele accessoires

- Ideaal voor het testen van materialen met hoge taaiheid en hoge hardheid onder extreme hoge belasting

- Levert stabiele prestaties en betrouwbare testgegevens voor rigoureuze materiaalevaluatie

Prijsvoordeel

Onze verticale integratie door interne R&D en productie maakt superieure kosten-prestaties mogelijk zonder afbreuk te doen aan de betrouwbaarheid. De lage uitvalfrequentie van de machine minimaliseert de onderhoudskosten en verbetert tegelijkertijd de operationele efficiëntie.

Deze uitzonderlijke kosten-prestatieverhouding levert tastbare voordelen op, waarbij premium kwaliteit wordt gecombineerd met concurrerende prijzen om uw investeringsrendement te maximaliseren.

Naleving van normen

ISO 6934 BS4449, ASTM C39, ASTM A370, ASTM E4, ASTM E8, ASTME9, ASTMA615, ISO6892, ISO7438, ISO7500-1, ISO 15630 EN10002-4, GB/T228-2002, GB 16491-2008, HGT3844-2008 QBT 11130-1991, HGT 3849-2008, GB6349-1986, ASTM C165, EN826, EN1606, EN1607, EN12430, etc.

Belangrijkste kenmerken

- Geïntegreerd systeem met geautomatiseerde controle, meting, data-acquisitie, weergave en resultaatverwerking

- Cilinder-onder-hoofdmotor configuratie met zeer nauwkeurige oliepomp en pc-gebaseerde servo-controller

- Multi-kanaals closed-loop controle voor volledige automatisering met uitzonderlijke stabiliteit

- Superieure professionaliteit, hoge betrouwbaarheid en eenvoudige upgradebaarheid

- Continue verbeteringsmogelijkheid om te voldoen aan de evoluerende industrienormen

Belangrijkste technische parameters

| Model |

WAW-1000D |

| Max. testkracht (kN) |

1000KN |

| Structuur |

Vier kolommen twee kogelomloopspindels, olie cilinder neerwaartse type |

| Belastingsbereik |

2%-100% |

| Middenbalk hefsnelheid (mm/min) |

200 mm/min |

| Max. trekruimte (mm) |

700mm |

| Max. compressieruimte (mm) |

600mm |

| Zuigerslag (mm) |

200mm |

| Gestrande draad klembereik |

Φ13-40mm |

| Vlakke monster klembereik |

0-30mm |

| Totaal vermogen |

3.2KW |

| Compressieplaat grootte |

Φ160mm |

| Buigondersteuning roller afstand |

300mm |

Veelgestelde vragen

V1: Is uw bedrijf een handelsonderneming of een productiefabriek?

A1: Wij zijn een fabriek-geïntegreerde handelsentiteit met 18 jaar specialisatie in testinstrumenten en 14 jaar export ervaring, waardoor directe kwaliteitscontrole met flexibele handelsdiensten mogelijk is.

V2: Hoe kan ik het meest geschikte product voor mijn behoeften selecteren?

A2: Ons technische team biedt optimale aanbevelingen op basis van uw testtoepassingen en vereiste specificaties (testtype, materiaal, belastingscapaciteit, nalevingsnormen).

V3: Wat zijn uw leveringsvoorwaarden?

A3: Standaardmodellen zijn doorgaans op voorraad. Niet-voorraadartikelen hebben een levertijd van 15-20 werkdagen na aanbetaling. Dringende vereisten kunnen worden geaccommodeerd met prioritaire productie.

V4: Biedt u aanpassingsdiensten aan?

A4: Ja, we bieden op maat gemaakte oplossingen die verder gaan dan standaardapparatuur. Deel uw specifieke behoeften en we streven ernaar om aan uw aanpassingsvereisten te voldoen.

V5: Kunnen we uw fabriek bezoeken voordat we een bestelling plaatsen?

A5: Absoluut. We verwelkomen bezoeken en helpen met hotelreserveringen en ophalen van de luchthaven voor uw gemak.

V6: Hoe wordt de machine verpakt voor transport?

A6: Alle instrumenten worden verpakt in exportwaardige houten kratten die voldoen aan internationale verzendnormen, met een bewezen staat van dienst van nul transportschade-incidenten.

Uw bericht moet tussen de 20-3.000 tekens bevatten!

Uw bericht moet tussen de 20-3.000 tekens bevatten! Controleer uw e-mail!

Controleer uw e-mail!  Uw bericht moet tussen de 20-3.000 tekens bevatten!

Uw bericht moet tussen de 20-3.000 tekens bevatten! Controleer uw e-mail!

Controleer uw e-mail!